Your Position:Home>News>Company news>Gas pipeline leakage rate reduced by 90%! Intelligent warning system solves operation and maintenance problems

Gas pipeline leakage rate reduced by 90%! Intelligent warning system solves operation and maintenance problems

With the popularization of clean energy applications, gas-fired generators have become the preferred choice for industrial and commercial users due to their high efficiency and low-carbon advantages. It is crucial to scientifically plan the computer room and gas pipeline system to ensure the safe and stable operation of the unit. As a professional natural gas power generation solution service provider, MaMa Li combines national standards and years of project experience to analyze key construction requirements for you.

Key Design Points for Gas Generator Room

1. Site selection and layout

The computer room should be far away from densely populated areas and flammable and explosive places, and the ground should be flat and have good load-bearing capacity. The distance between the unit and the wall should be ≥ 1.5 meters, with reserved maintenance channels and an independent ventilation system to ensure air circulation.

2. Safety protection measures

The computer room needs to adopt explosion-proof lighting and electrical equipment, equipped with combustible gas leakage alarm devices, and linked emergency shut-off valves. The wall must achieve a 2-hour fire rating and be equipped with an automatic fire extinguishing system. At the same time, installing sound insulation materials to control noise levels below 85 decibels.

3. Ventilation and heat dissipation

Adopting a forced exhaust design, with a minimum of 15 air changes per hour. The air inlet and exhaust outlet should be arranged diagonally to avoid airflow short circuits, and explosion-proof axial fans should be installed in high-temperature areas to assist in heat dissipation.

Technical requirements for gas pipeline system

1. Material and installation specifications

Priority should be given to seamless steel pipes or PE pipes, and the interface should be sealed using argon arc welding technology. The pipeline slope should be ≥ 0.3% and drainage devices should be installed. The outdoor part should be treated with anti-corrosion and insulation, and the burial depth should not be less than 0.8 meters.

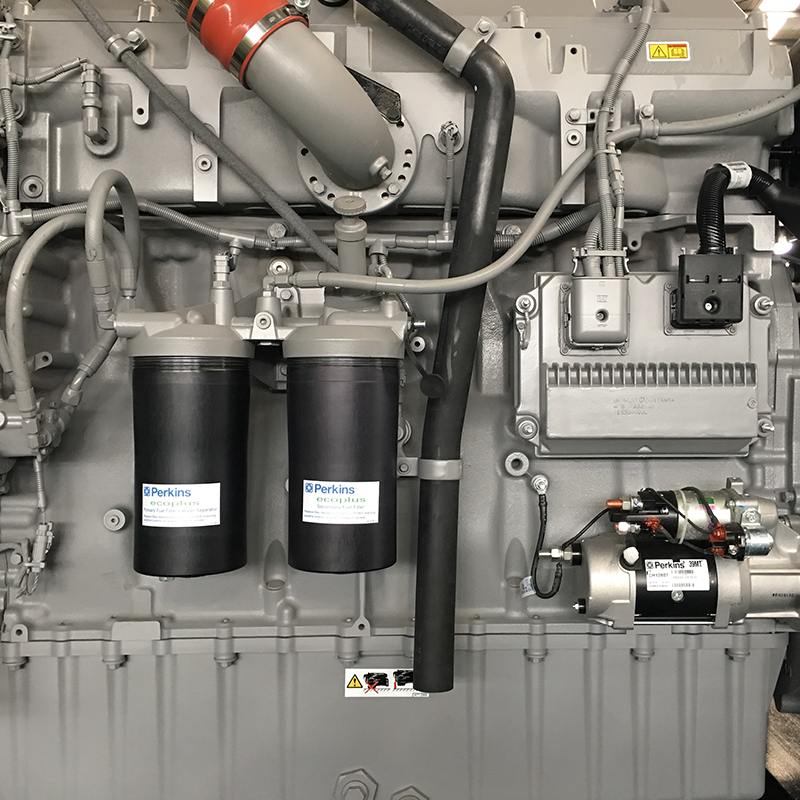

2. Security protection configuration

The main pipeline must be equipped with emergency shut-off valves, pressure regulating devices, and overcurrent protectors, and branch pipelines must be equipped with flame arresters. Pressure gauges, flow meters, and other instruments need to be regularly calibrated, and valve operation markings should be clear and distinguishable.

3. Testing and maintenance

After the completion of the system, a 1.5 times working pressure air tightness test is required, and professional equipment is used to detect leakage points before operation. Conduct monthly pipeline wall thickness testing in daily operation and maintenance, and establish digital inspection records.

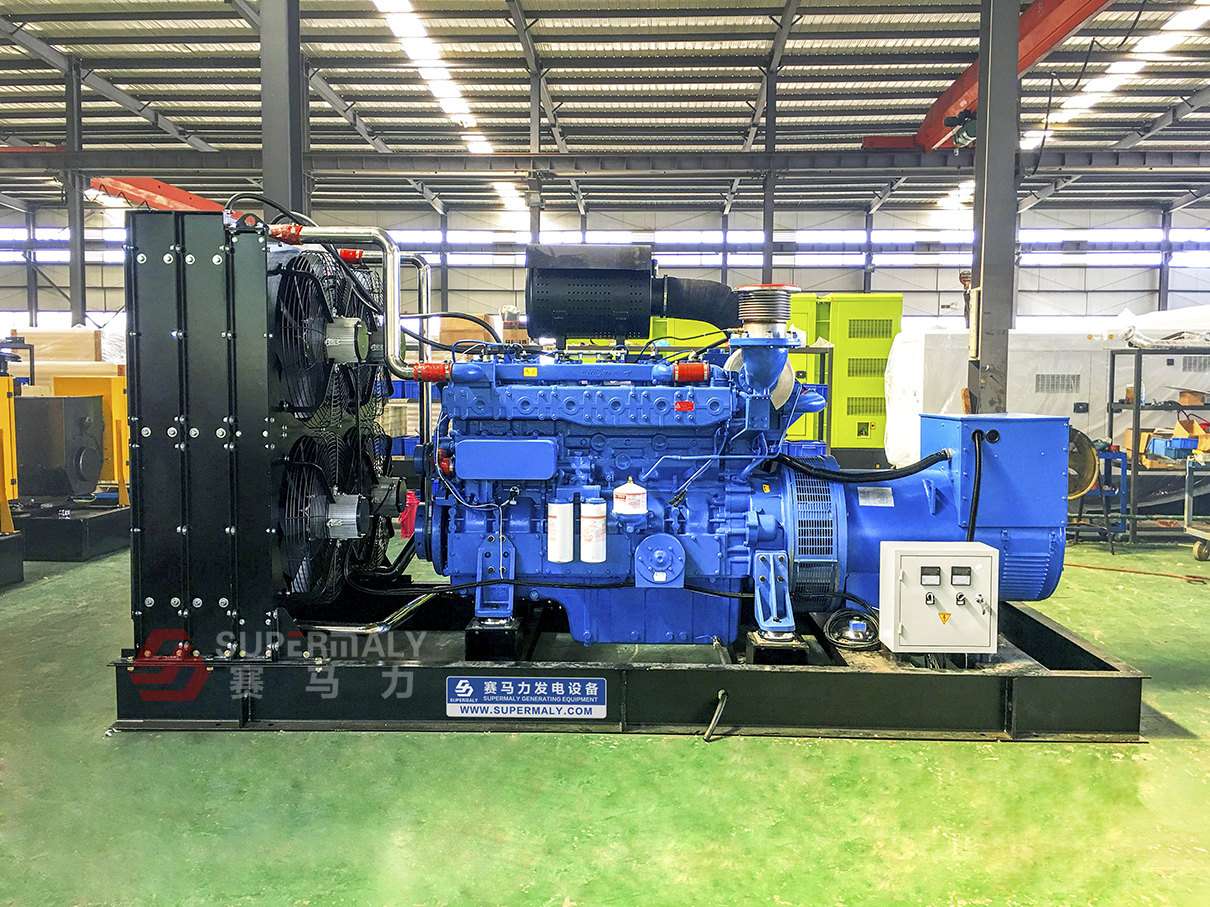

Core advantages of Shandong Supermaly Power Generation Equipment Co., Ltd

Having over 150 intellectual property rights, the company has won multiple national and provincial honors, and has passed multiple certifications such as CE and ISO. The products are exported to more than 80 countries and regions in Europe, Asia, South America, Africa, etc., and rank first in market share in countries such as the Philippines, Russia, and Colombia.

Choose a major, choose peace of mind! If you need customized computer room construction plans or technical consultation, please contact our online customer service. Our engineering team will provide you with comprehensive support.

- Strong | The 125th Canton Fair ended successfully, and high-end customers chose it here!

- New arrivals, full of rewards! Supermaly cippe2019 oil show ended successfully!

- Supermaly | Helping the construction of the “Belt and Road” and opening up a new pattern of “going out”

- The difference between gas generator sets and diesel generator sets

- Small class of knowledge | The greater the load on the diesel generator set, the higher the fuel consumption?

- Supermaly reminds you to pay attention to the following items when using diesel generator sets in summer

- Why the generator set pull the cylinder and the characteristics of the cylinder after the pull

- Reasons for Black Smoke in Diesel Generating Set

- How to avoid some of the risks during the installation of diesel generators

- Maintenance and service about diesel generators and gas generators

- The four roles of diesel generator sets

- Matters choose diesel generator sets to note

Chinese

Chinese  English

English  Russian

Russian  Spain

Spain