Your Position:Home>News>Industry news>Detailed explanation of the four key ventilation systems in Cummins computer rooms

Detailed explanation of the four key ventilation systems in Cummins computer rooms

A good ventilation system is a key guarantee for the efficient and safe operation of the generator room, which not only affects the performance of the unit, but also involves environmental protection and safety.

The ventilation system design of Cummins generator room is a key factor in ensuring the normal operation of the unit and extending its service life. A complete computer room ventilation system mainly includes the following four systems, each of which is crucial:

1. Regular ventilation system

The ventilation and air exchange system for the Cummins diesel generator unit room is generally 10-15 times the ventilation rate. Only the exhaust fan can be installed. If there is gas fire extinguishing in the water supply and drainage, this system also needs to undertake the exhaust system after the fire extinguishing is completed.

2. Cummins Generator Process Inlet and Exhaust Air System

The motor itself has a large exhaust duct, which is built-in to the generator. We can add an air shaft and design an intake system to supplement the exhaust air volume and the combustion air volume of the generator set (electrical equipment). We also install a supply fan, which has a large air volume.

This system is also designed to reserve a ventilation shaft, which is not related to the generator quotation.

3. Cummins diesel generator exhaust system

When it comes to environmental issues, it is usually referred to as a "smoke exhaust pipe". The generator comes with it, and the electrical standard atlas also includes a dedicated well for this system. In fact, it is difficult for engineering design buildings to have so much open space. Most of them are discharged from the generator exhaust shaft to the outside. If you have any questions, you can directly contact the generator manufacturer.

4. Oil storage room exhaust system

Can be used in conjunction with 1, with check valves and fire dampers installed on the branch pipes leading to the oil storage room; It is also possible to set up a separate system and use explosion-proof ventilation fans.

2、 The ventilation of Cummins diesel generator unit room includes two parts, normal ventilation and working ventilation.

Regular ventilation: The machine rooms of air-cooled and water-cooled generators should have a ventilation frequency of 6 times, and the ventilation frequency of the oil storage room should not be less than 3 times. For computer rooms equipped with gas fire extinguishing systems, this ventilation system is responsible for eliminating indoor exhaust gases after a fire, but it is not emergency ventilation.

Work ventilation: Cummins diesel generator sets must consider the required air volume for oxygen consumption during operation; The air-cooled generator has a large cooling air volume and generally uses natural air intake. The diesel engine comes with a fan pressure discharge, but the 250kw Cummins diesel generator set comes with a fan pressure head of only about 150Pa. When the shaft resistance is high, a fan needs to be added to overcome the shaft resistance. Generally, when the inlet shaft resistance is high, a fan is added; If the resistance of the exhaust shaft is high, add an exhaust fan.

The Cummins diesel generator room adopts gas fire extinguishing, and electromagnetic valves should be installed on the inlet and exhaust channels. When a fire occurs in the 250kw Cummins diesel generator room and gas fire extinguishing is started, these valves should be interlocked and closed to ensure the fire extinguishing effect.

Cummins diesel generator sets use pressurized exhaust, with high flue gas temperature and airflow velocity. The flue gas needs to be discharged at high altitude, and insulation should be considered for the smoke pipe. At the same time, shock-absorbing hangers should be installed.

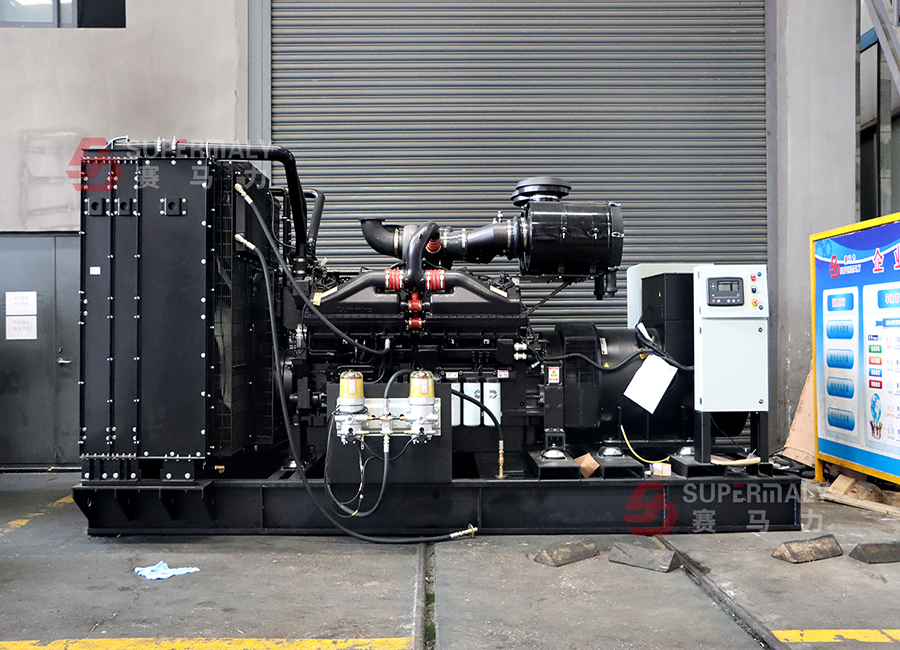

By scientifically planning the above four ventilation systems and ensuring that the air inlet is far away from the exhaust outlet to prevent hot air from flowing back. Shandong Supermaly Generating Equipment Co., Ltd. adopts world-renowned brand generators such as CUMMINS, PERKINS, DEUTZ, ISUZU, RICARDO, VOLVO, etc., which can provide reliable, stable, and environmentally friendly power guarantee for key facilities such as data centers, hospitals, and industrial parks. The power covers 8-4500KW and is exported to more than 80 countries and regions. We have been deeply involved in the power generation equipment industry for many years and are committed to becoming a globally trusted expert in green energy!

- Strong | The 125th Canton Fair ended successfully, and high-end customers chose it here!

- New arrivals, full of rewards! Supermaly cippe2019 oil show ended successfully!

- Supermaly | Helping the construction of the “Belt and Road” and opening up a new pattern of “going out”

- The difference between gas generator sets and diesel generator sets

- Small class of knowledge | The greater the load on the diesel generator set, the higher the fuel consumption?

- Supermaly reminds you to pay attention to the following items when using diesel generator sets in summer

- Why the generator set pull the cylinder and the characteristics of the cylinder after the pull

- Reasons for Black Smoke in Diesel Generating Set

- How to avoid some of the risks during the installation of diesel generators

- Maintenance and service about diesel generators and gas generators

- The four roles of diesel generator sets

- Matters choose diesel generator sets to note

Chinese

Chinese  English

English  Russian

Russian  Spain

Spain